Why 2025 Is the Smart Year to Upgrade Your Roland DG Equipment in Colorado

See the latest Roland DG machines in action – book your demo now.

The Best of PRINTING United 2025: Roland DG Innovation Unleashed

If you’re running a print shop, signage business, or graphics operation in Colorado, chances are you’ve been watching the tech landscape for your next big upgrade. At PRINTING United 2025, Roland DG came in hot with a wave of innovative new machines designed to transform production capabilities across the board. Whether you’re based in Denver, the Front Range, or mountain towns serving ski tourism and boutique retail, these machines are built to match Colorado’s demanding, high-variation market.

From high-speed eco-solvent printers to compact UV flatbeds and dimensional wall covering devices, Roland’s lineup checks all the right boxes for shops that need speed, versatility, ROI, and creative freedom.

In this blog, you’ll get an in-depth look at the new Roland DG devices launched at PRINTING United 2025, why now is the ideal time to upgrade, and what trends Roland is aiming to lead in 2026.

Highlights from Roland DG at PRINTING United 2025

1. TrueVIS XP-640: Ultra-Fast Eco-Solvent Printing

Designed for maximum productivity without compromising color or image quality, the XP-640 is Roland’s answer to the modern, high-demand print shop. The device delivers exceptional speed, supports high-capacity media rolls, and maintains the trusted Roland color accuracy. If you’re in vehicle wraps, outdoor banners, or large-format retail signage, this is a must-have.

Why it matters:

- Speeds up vehicle wrap production for time-sensitive jobs

- Handles high-volume roll printing for expo graphics

- Durable prints suitable for Colorado’s varying climate

2. TrueVIS XG-640: All-in-One Print & Cut Workhorse

The XG-640 combines robust printing capabilities with precision cutting, enabling your team to streamline production without juggling multiple machines. For print businesses producing stickers, decals, custom signage, or apparel transfers, this device simplifies your workflow.

Why it matters:

- Reduces equipment footprint

- Speeds up decal production

- Ideal for sticker shops and event graphics

3. VersaOBJECT MO Series: Desktop UV Flatbed Power

The MO Series brings industrial-grade UV flatbed functionality into a compact benchtop footprint. Perfect for businesses diversifying into personalization, packaging, or direct-to-object printing, it opens up new revenue streams by supporting varied substrates and object surfaces.

Why it matters:

- Supports printing on items up to 8 inches thick

- Great for boutique retail, custom gifts, and POP displays

- Perfect entry point into UV for small shops

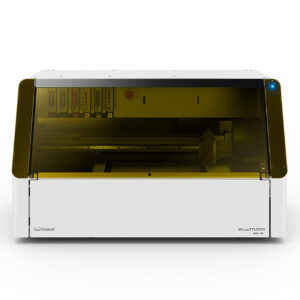

4. VersaSTUDIO BN2-30 & BD-12: Compact & Capable

Smaller doesn’t mean slower. The BN2-30 eco-solvent print/cut combo and BD-12 desktop UV flatbed pack serious punch for smaller businesses or those adding specialty services. Whether you’re printing stickers or personalizing phone cases, these units allow for high-quality output in tight spaces.

Why it matters:

- Affordable entry-level or secondary unit

- Perfect for home-based or small-scale commercial shops

- Compatible with a wide variety of substrates

5. DIMENSE DA-640: Textured & Tactile Printing

This revolutionary device enables printing dimensional textures and raised surfaces. Ideal for wall decor, interior design applications, or immersive branding installations, the DA-640 takes flat signage to a new level—literally.

Why it matters:

- Creates eye-catching dimensional graphics

- Expands your offerings for hospitality and tourism industries

- Helps set your shop apart from flat-print competitors

6. Roland DG Software Upgrades: VersaWorks 7 & DG Connect

Software is the backbone of modern print shops. VersaWorks 7 enhances print precision and RIP efficiency, while Roland DG Connect allows remote monitoring, analytics, and proactive maintenance.

Why it matters:

- Optimizes print production across multiple jobs

- Minimizes downtime with predictive diagnostics

- Increases profitability through automation

Why NOW Is the Best Time to Upgrade

Colorado print businesses are operating in a highly diversified environment—outdoor graphics, ski resort branding, retail signage, and trade show materials all demand speed and precision. Here’s why 2025 is the sweet spot to upgrade your Roland equipment:

- Market Shifts: Shorter lead times, higher personalization, and increased material variety are reshaping client expectations.

- Better ROI: New Roland devices dramatically increase productivity while opening new markets (textured print, UV object printing, custom gifts).

- Labor Efficiency: With staffing still tight, automated job management and RIP software help stretch your team’s capacity.

- Technology Leap: Waiting could put your business behind competitors who adopt now and start capturing new revenue streams.

- Tax Planning: Upgrading before year-end may qualify for equipment deductions and financing advantages.

How to Choose the Right Roland for Your Business

Not all upgrades are created equal. Before pulling the trigger, assess your needs based on:

- Job Type: Are you producing wraps, decals, wall graphics, or gift items?

- Substrate Range: Do you need to print on rigid, flexible, 3D, or textured materials?

- Speed & Volume: How many jobs are you handling daily? Are peak seasons stressing your equipment?

- Space: Do you have room for new equipment, or do you need compact solutions?

- Workforce: How experienced is your team? Do you need easier, more automated interfaces?

Match your needs to the right device:

- XP-640 / XG-640: High-volume wrap, signage, decal production

- MO Series: Personalization and rigid object printing

- BN2-30 / BD-12: Entry-level or supplemental shop operations

- DA-640: Textured graphics for decor or high-impact branding

What to Expect from Roland in 2026

If you’re future-planning, Roland has already signaled big moves for next year:

- Advanced Automation: Expect integrated finishing, robotic handling, and enhanced AI job-routing.

- Wider Substrate Compatibility: Including textiles, specialty plastics, and metals.

- Eco-Sustainability: More eco-conscious ink formulations and energy-efficient devices.

- Enhanced Cloud Features: Smarter DG Connect platform with better analytics and reporting.

- Hybrid Machines: Devices that combine roll and flatbed capabilities in one footprint.

Even if you upgrade now, planning for 2026 means looking for modular expansion paths or trade-in value that supports a two-phase equipment evolution.

Final Thoughts & Action Plan

2025 isn’t just another trade show year—it’s the turning point for print businesses who want to gain a competitive edge through innovation. Roland DG has delivered not only advanced print engines but also tools for personalization, dimensional effects, and data-driven production.

If you’re in Colorado, you’re operating in a unique market that demands versatility, creativity, and speed. Roland’s new lineup hits all those marks.

Next Steps:

- Book a demo with a ABT

- Audit your current device performance & job bottlenecks

- Calculate ROI based on new revenue streams and time savings

- Train your team on new software (VersaWorks 7, DG Connect)

- Plan a 2-year equipment roadmap to align with Roland’s 2026 innovations

Don’t miss your chance to lead the market.

Let us show you how upgrading in 2025 will fuel your print business growth for years to come.

Roland DG technology + Colorado ambition = Unstoppable Print Potential.