🌞 Summary Overview

In Colorado’s intense sun and high-altitude climate, outdoor banners face unique challenges: rapid fading, color shift, and material degradation. To ensure your Roland‑printed banners shine and endure, you need a robust color management strategy tailored to this environment. This post covers:

- The factors in Colorado’s sun affecting your prints

- Roland’s ink and media tech for durable outdoor use

- How to optimize ICC profiles, color gamuts, and RIP settings

- Finishing techniques to enhance longevity

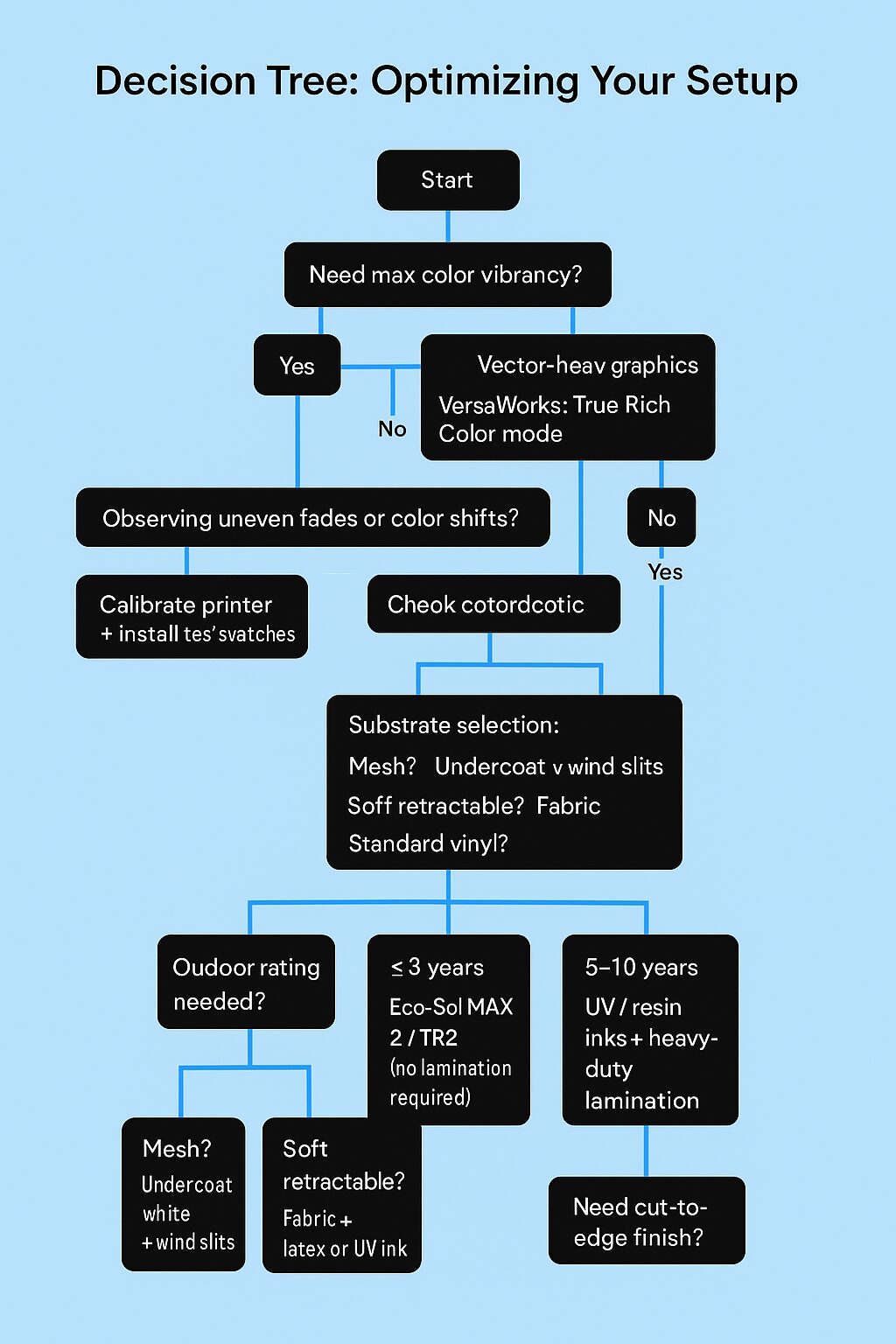

- A decision tree to guide equipment and workflow choices

By the end, you’ll be equipped to create vibrant, long-lasting outdoor banners that withstand UV exposure and impress your clients.

1. Why Color Management Matters in High‑UV Denver

A. UV Intensity & Altitude Effects

Denver sits over 5,000 ft above sea level (5,280 to be exact), which means up to 25% more UV exposure compared to sea level. This increases:

- Accelerated pigment fading, especially in the first six months

- Inconsistent color output, varying between print runs if not carefully managed

- Material stress, leading to cracking, curling, or delamination

B. Maintenance of Brand Integrity

Businesses rely on consistent logos and brand imagery. Without proper calibration, vibrant brand colors can look washed‑out or inconsistent across banners. Your brand is your business—how your banners look matters.

C. Cost & Customer Trust

Poor outdoor performance leads to reprints, unhappy clients, and waste. Effective color management reduces both cost and frustration.

2. Leveraging Roland’s Outdoor Color Technology

A. Advanced Ink Formulations

- Eco‑Sol™ MAX 2 / TR2 Inks: Robust eco‑solvent inks with vibrant output and up to 3 years outdoor life without lamination.

- TrueVIS Latex Inks: Fast curing and scratch‑resistant, great for outdoor durability.

- UV‑curable and resin inks: Offer up to 7–10 years outdoor resilience when laminated and mounted correctly.

B. Durable Media Selection

Choose substrates designed for high‑UV exposure:

- PVC banner vinyl (13–15 oz): Industry‑standard with proven durability.

- Mesh vinyl: Reduces wind stress while maintaining vibrant color.

- Lightweight or soft fabric banners: Good for retractables; choose polyester for smoother dye adhesion.

C. VersaWorks RIP Color Controls

Roland’s VersaWorks 7 includes:

- True Rich Color mode: Uses Roland DG WideGamut CMYK profiles for punchy output on vector-heavy designs.

- Perceptual intent: Ideal for photographic content to preserve tonal relationships.

- White ink undercoats: Boost contrast on dark or clear substrates.

3. Step-by-Step Color Management Workflow

A. Proof with ICC Profiles

- Embed device profiles: Use Roland-supplied profiles (Eco‑Sol MAX 2, TR2, Latex, UV).

- Enable “Use Embedded ICC Profile” in VersaWorks when designer files include color tags.

B. Choose Rendering Intent

| Type of Graphic | Recommended Intent | Why |

|---|---|---|

| Bold vector/logos | True Rich Color | Brings maximum vibrancy. |

| Photos | Perceptual | Maintains tonal realism. |

C. Apply White Undercoat Strategically

Only use it under dark substrates. Avoid overuse to prevent ink opacity from blocking UV resistance.

D. Conduct Test Prints

Use banner scraps to test:

- Color accuracy

- Lightfastness

- Outdoor drying and adhesion

This step helps validate profile selections before full runs.

4. Finishing & Protection Techniques

A. Lamination for UV Defense

Even inks rated for 3 years can benefit:

- Lexan/polycarbonate overlaminate extends life by 2–4×.

- Gloss vs. matte options enhance UV resistance and finish aesthetics.

B. Reinforced Edges & Grommets

- Double‑stitched hems resist chain tension.

- Aluminum “C”‑rail pockets reduce curling at high elevations.

C. Edge Sealing & Wind Slits

- Seal edges with silicone or thermoplastic to prevent moisture and UV damage.

- Install wind slits on mesh banners for reduced wind load.

5. Advanced Tips to Maximize Results

- Monitor calibration with a 128‑step chart at least monthly.

- Check color plots under sun and shade to ensure consistency.

- Build an outdoor environmental profile for seasonal UV variations.

- Use Roland Color Library with VersaWorks for accurate Pantone matching.

- Enable variable data printing for batch consistency on short runs.

6. Real‑World Case: Colorado Sports Festival

Context: City event banners along a sunny mile‑long parade route

Solution Steps:

- Chose 13 oz PVC with wind slits

- Set VersaWorks to True Rich Color

- Used Roland Eco‑Sol MAX 2 ink

- Laminated in gloss Lexan

- Installed reinforced hems

Results:

- Over 8 months, no visible fading in direct sun

- High praise for brand consistency across banners

- 30 % fewer reprints compared to prior methods

✅ Conversion & Next Steps

With Colorado’s intense UV exposure and business branding demands, implementing optimized color management and finishing methods isn’t optional—it’s essential.

Next steps you can take:

- Set up a color calibration schedule

- Reprovision media to Roland‑certified high‑UV vinyl

- Adopt lamination workflows if lifespan targets exceed 3 years

- Train your team on VersaWorks settings and ICC profiling

Ready to power up your banner game?

Explore Roland’s latest Eco‑Sol MAX 2 and TR2 inks, plus VersaWorks configurations at ABT. We also offer full‑service calibration support, Roland‑certified media selection, and ROI‑driven workflow audits.

👉 Start here to request a free Denver‑area consultation. Let’s help you deliver outdoor banners that resist fading, maintain brand integrity, and impress for years.