How to Test UV Ink Adhesion: A Complete Guide for Colorado Businesses

Whether you’re printing promotional signage, custom packaging, or industrial labels, the durability and quality of your print jobs hinge on one critical factor: ink adhesion. Specifically, UV ink adhesion plays a massive role in the success of any job that demands long-lasting, scratch-resistant prints on non-porous surfaces like plastics, metals, acrylics, and glass.

At ABT, we work with a range of Colorado businesses—from creative agencies and print shops to manufacturers and industrial producers—who rely on high-quality UV printing solutions to get the job done right. Whether you’re using Canon, Epson, HP, Kyocera, or Roland printers, understanding how to properly test UV ink adhesion can save you time, reduce waste, and keep your customers coming back.

In this blog, we’ll walk you through:

- What UV ink adhesion is

- Why testing matters

- How to conduct a proper test (including the tape test)

- Recommended printers and inks

- Best use cases by industry

- Troubleshooting poor adhesion

- ABT’s solutions for UV printing in Colorado

What Is UV Ink Adhesion?

UV (ultraviolet) ink is a specialized ink that cures instantly when exposed to UV light. That curing process bonds the ink to the substrate, making it highly durable and resistant to scratches, chemicals, and weather.

But here’s the kicker: Not all surfaces are created equal.

Some materials bond beautifully with UV ink, while others may cause flaking, cracking, or poor adhesion. That’s why it’s essential for you to test ink adhesion before running a full print job, especially when working with unfamiliar or coated substrates.

Why Is Ink Adhesion So Important?

Poor adhesion can lead to a host of issues:

- Peeling and flaking prints

- Customer complaints and rework

- Wasted materials and ink

- Loss of credibility with clients who expect long-lasting results

When you’re printing onto challenging substrates—like polycarbonate, acrylic, aluminum, or PVC—ink adhesion becomes even more crucial. Whether you’re doing one-off prototypes or mass production runs, getting this right the first time saves you hours and hundreds of dollars.

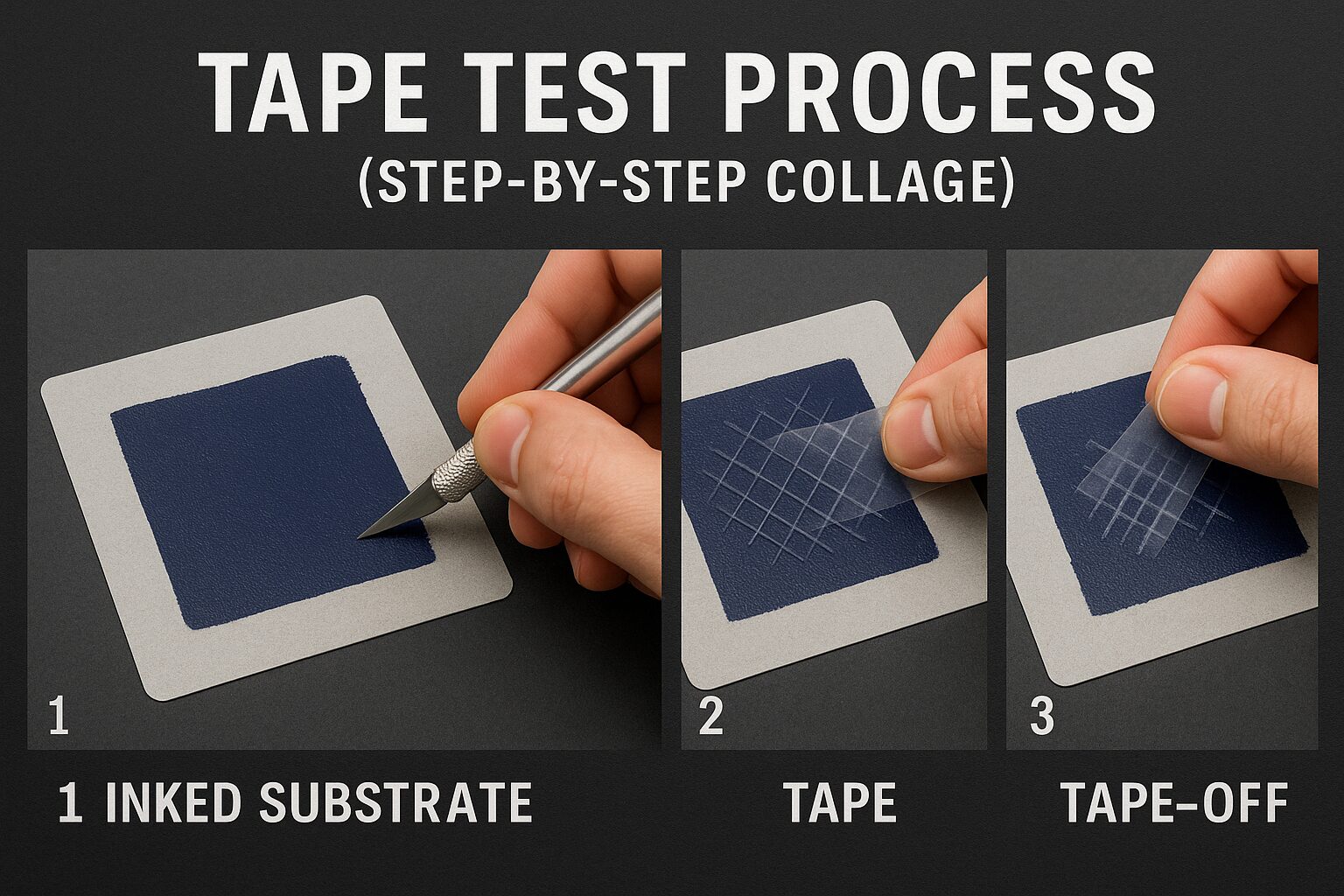

How to Test UV Ink Adhesion (The Tape Test Method)

The most widely accepted and practical method for testing UV ink adhesion is the tape test. Here’s how you can do it in your own print environment.

What You’ll Need:

- A sample print using your UV printer

- 3M Scotch® 610 tape or similar adhesive tape

- A utility knife or cutter

- Your substrate (glass, acrylic, metal, etc.)

Step-by-Step Instructions:

- Print and Cure the Sample

Use your UV flatbed printer or hybrid UV printer to print a small section on your substrate. Make sure your curing settings (lamp intensity, speed, ink volume) are optimal. - Wait for Full Cure

Allow the ink to cool and settle for at least 10–15 minutes, or longer depending on ambient temperature and humidity. - Cut a Hatch Pattern

Using a cutter or utility knife, make a grid or hatch pattern (crosshatch) on the printed area. The lines should be about 1mm apart in both directions to test adhesion across small segments. - Apply the Tape

Firmly press a strip of 3M 610 tape over the crosshatched area. Use your finger or a roller to make sure the tape fully contacts the ink surface. - Pull the Tape Off

Peel the tape back quickly at a 180-degree angle (flat against the surface, not upward). - Evaluate the Results

Look at how much ink is removed by the tape. A good adhesion test will show no ink lifting or minimal removal.

Tip: Keep a log of substrate types, print settings, and adhesion results to streamline future jobs.

Top UV Printers and Ink Systems for Reliable Adhesion

At ABT, we partner with brands that have proven their reliability and versatility in UV printing. Here are our top recommendations:

Roland VersaUV Series (LEF2-200, LEF2-300)

- Type: Flatbed UV printer

- Best For: Custom promotional items, small signage, industrial labels

- Inks: Roland EUV/EUV5 inks

- Feature: Built-in primer options and support for difficult substrates like glass and metal

Canon Arizona 135 GT

- Type: Flatbed UV printer

- Best For: Large format signage, high-volume print shops

- Inks: Canon IJC358 ink set (UV-curable)

- Feature: VariaDot imaging for precise droplet control

Epson SureColor V7000

- Type: 4’x8′ Flatbed UV printer

- Best For: Rigid signage, acrylic displays, corrugated packaging

- Inks: Epson UltraChrome UV ink set

- Feature: High-opacity white ink and vivid color for layering

HP Latex R-Series (R1000, R2000)

- Type: Hybrid UV/latex printer

- Best For: Mixed media, retail graphics, outdoor signage

- Inks: HP Latex inks

- Note: Eco-friendly and excellent adhesion across diverse substrates

Best Use Cases by Industry

Retail & POP Displays

Substrates: Acrylic, foam board, PETG

Use: Displays, shelf talkers, window graphics

Ideal Printer: Epson SureColor V7000

Manufacturing & Industrial Labeling

Substrates: Aluminum, polycarbonate, powder-coated metals

Use: Equipment tags, compliance labels

Ideal Printer: Roland LEF2-300

Custom Promotional Products

Substrates: Wood, glass, metal, pens

Use: Branded giveaways

Ideal Printer: Roland LEF2-200

Architectural & ADA Signage

Substrates: PVC, acrylic, laminate

Use: Directional signs

Ideal Printer: Canon Arizona 135 GT

Packaging Prototypes & Short Runs

Substrates: Cardboard, rigid plastics

Use: Packaging samples

Ideal Printer: HP Latex R1000

Troubleshooting Poor Ink Adhesion

- Dirty Substrate: Clean surfaces with isopropyl alcohol

- Incorrect Curing Settings: Adjust UV lamp intensity or slow print speed

- Wrong Ink: Use compatible inks or primers

- Low Surface Tension: Consider flame/corona treatment

- Old Ink: Always check expiration and storage

How ABT Supports Colorado Businesses with UV Printing

At ABT, we go beyond products—we partner with you to ensure your UV printing is reliable, profitable, and Colorado-tough.

- On-site printer demos

- Substrate testing and sample evaluations

- Operator training and support

- Managed Print Services to keep you running

- Local support across Denver, Boulder, and Colorado Springs

Final Thoughts: Mastering UV Ink Adhesion Starts with Testing

UV printing opens up new opportunities—but only if your ink bonds properly. A simple tape test can prevent production issues and boost customer satisfaction.

Need help with printers, inks, or adhesion testing? Reach out—we’re here to help Colorado businesses print smarter, not harder.

📞 Contact ABT

Phone: (303) 778-0600

Email: info@yourabt.com

Website: www.yourabt.com